If you want to manage and control Hand Arm Vibration risk then measuring an individual’s vibration exposure is a must. In this article we look at how to use the vibration exposure points system to do this.

Why do you need to measure vibration?

The key reason for measuring vibration is to reduce the risks of your employees developing hand-arm vibration syndrome (HAVS). You should use a hand-arm vibration meter to measure the vibration magnitude of tools if:

- Suitable vibration data is not readily available

- You are unable to make a reasonable estimate of the vibration exposure level and you can’t say with any confidence whether the Exposure Action Value (EAV) has been exceeded or not.

- You need reassurance that the data you have used is accurate

- You need measurements to confirm whether any control measures you have put in place are successful

- You need your own measurements to give you data with which to fight personal claims.

Vibration assessments apply to companies large and small, and the HSE in the UK recommends that even companies with less than 5 employees should record any Hand-Arm Vibration findings, even if the levels are low, and review their assessments.

Reliability of manufacturers data

Whilst manufacturers data can be useful in comparing one tool with another especially for ‘buy smooth’ procurement decisions, when carrying out a vibration assessment, it is vital to collect your own vibration data for each piece of equipment used, and for each kind of task it is used for. You cannot simply rely on manufacturers data, this is because the tools are used in ‘favourable’ factory conditions and how you use the tool or it’s age or level of maintenance could be completely different. As alternatives to using manufacturers data, the HSE provides a table of expected levels of vibration from different tools which can be used as an initial assessment – but not in the full risk assessments.

Job-based vibration exposure

In the recently updated (2019) Control of Vibration at Work Regulations the emphasis of vibration risk assessments has changed a little. The HSE in the UK now prefers that employers record results on a job basis rather than an individual task and risk basis. If you already have vibration data and risk assessments, this change in emphasis may mean you need to change the way you currently measure vibration exposure and the way your data is reviewed.

In this case, it will be much easier to add up all the vibration exposure points for a person’s job rather than the vibration magnitude data and time to reach the action (or limit) values.

How do you measure it?

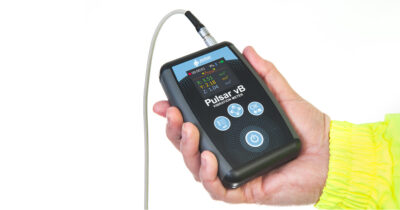

Instruments such as the Pulsar vB use a tri-axial accelerometer to measure the vibration transferred from a tools handle (or handles) to a workers hand. The Pulsar vB measures the vibration magnitude in meters per second squared (m/s2) – the vector sum of the three axes – and references this over a standard 8-hour day as the daily exposure A(8), as well as giving you the exposure points and the time to reach the EAV and Exposure Limit Value (ELV).

If you don’t use a meter that gives you the vibration exposure points then you can enter the vibration magnitude data into the HSE’s vibration calculator along with the duration (trigger time) and it will calculate the points for you.

Exposure Levels

The hand-arm vibration exposure levels set out in the Control of Vibration at Work Regulations 2005 are:

| Vibration Magnitude (over and 8-hour reference period) | Vibration Exposure Points | |

|---|---|---|

| The daily Exposure Limit Value (ELV) | 5.0 m/s2 A(8) | 400 points |

| The daily Exposure Action Value (EAV) | 2.5 m/s2 A(8) | 100 points |

The limit value must never be exceeded in a workers day, and employers should aim to reduce levels of vibration to ‘As Low a level As is Reasonably Practicable’ (ALARP) – at the very least the aim should be to be below the EAV (below 100 points).

Using Vibration Exposure Points

The action value of 100 points is made up of all the trigger times from all the tools used by a worker in their job on any given working day. Assessing points per hour, or per 15 mins trigger time seems to work well for most tools. It is much simpler to add the points up and use a Ready Reckoner (based on the HSE’s) to identify overall vibration exposure than to add the vibration magnitude (A(8) Vector Sum data) of individual tools. On the Ready Reckoner, the exposures for different combinations of vibration magnitude and exposure time are given in exposure points instead of values in m/s2 A(8). Note that:

- Exposure points change simply with time: twice the exposure time, twice the number of points;

- Exposure points can be added together, for example where a worker is exposed to two or more different sources of vibration in a day;

- The EAV (2.5 m/s2 A(8)) is equal to 100 points;

- The ELV (5 m/s2 A(8)) is equal to 400 points;

If the tool you are measuring has two handles, for instance on some strimmers or chainsaws, you should measure vibration from both (as there are two places for the operator to receive vibration), but always take the higher value when assessing exposure.

The Pulsar vB shows the Exposure Points for periods of 15 minutes, 30 minutes and 1 hour. The values are also colour-coded to give instant visual indication and are based on criteria in the UK specified by the HSE.

Advantages of Vibration Exposure Points

- Easy to add up the points

- Straightforward for everyone to understand

- Simple to mark up tools as High, Med and Low Risk based on the points values.

Disadvantages

When people use tools for only a short time (less than a minute e.g. an impact wrench undoing wheel nuts) accurate counting of exposure trigger time is difficult, but by including a minimum 15-minute period for all points measurements we err on the side of caution – so this is not a real problem!

Controlling exposure

A Total Exposure Point value of 100 or greater indicates increased risk to employees, and administrative or engineering controls should be considered to decrease risk. A Total Exposure Point value of 400 or greater indicates safe limits have been exceeded and employees are at significant risk of developing HAVS, and controls should be implemented immediately to reduce vibration magnitude exposure.

Control measures should be introduced whenever an employee’s daily exposure to vibration is likely to reach or exceed the EAV (100 points). Efforts should always be made to reduced levels of vibration to ALARP. Limiting the duration of exposure is considered in the Regulations to be a last resort when all other control methods are not enough. Ways to limit exposure can include encouraging staff to take regular breaks to help mitigate the effect of exposure.

Key control methods are:

- Use a Hand Arm Vibration Meter (HAV meter), such as the Pulsar vB to:

- carry out a risk assessment from the vibration exposure from power tools

- set usage limits of high vibration tools

- identify daily vibration exposure limits for each worker

- Train staff to use the correct tools for the job, in the correct way

- Look for engineering solutions and alternative means of carrying out work

- Ensure tools are well maintained

- Buy smooth! Use low vibration tools where appropriate*

- Encourage staff to take regular breaks from their tools by doing other jobs in between

- Encourage good blood circulation by keeping warm and encouraging staff to give up smoking

*Common misconception: It’s a misconception that low vibration tools are safer to use, just because a tool has a higher vibration output, could mean your duration using that tool is less. Companies sometimes jump from higher vibration tools thinking they are protecting their employees, when they are not. As long as you keep an eye on duration of work lower vibration tools can work. And sometimes higher vibration tools can be better if they drastically reduce the duration of any given task.

Whole-body vibration

The discussion above equally applies as much to whole-body vibration as it does to hand-arm.

The whole-body vibration exposure levels set out in the Control of Vibration at Work Regulations 2005 are:

| Vibration Magnitude (over an 8-hour reference period) | Vibration Exposure Points | |

|---|---|---|

| The daily Exposure Limit Value (ELV) | 1.15 m/s2 A(8) | 400 points |

| The daily Exposure Action Value (EAV) | 0.5 m/s2 A(8) | 100 points |

The limit value must never be exceeded in a workers day, and employers should aim to reduce levels of vibration to ‘As Low a level As is Reasonably Practicable’ (ALARP) – at the very least the aim should be to be below the EAV (below 100 points).

You might also like:

- 8 Top tips for preventing HAVS

- HAVS Fines: Can you afford not to measure Hand Arm Vibration

- HAV some common sense

- Pulsar’s Employers’ Guide: 5 steps to controlling Hand-Arm Vibration

References

Health and Safety Executive (2019). Hand-Arm Vibration. Control of Vibration at Work Regulations 2005: Guidance on Regulations. TSO, 2nd Ed.

Health and Safety Executive Website (2019). Hand-Arm Vibration Ready Reckoner. Available online.