Many businesses focus their health and safety efforts on managing the hazards that pose physical safety risks to their staff, the occupational health risks can be easily missed. The main occupational health risk associated with the manufacturing sector is noise. This article looks at how to control and prevent noise-induced hearing loss (NIHL) in the manufacturing industry.

Harmful levels of noise can lead to serious health and safety issues such as noise-induced hearing loss, ringing in the ear or other conditions for all workers including those employed in manufacturing. Over time, if the noise from factory tools, machinery and processes is loud consistently and not monitored or controlled, workers who are exposed to it will suffer permanent hearing loss.

Noise-hearing loss in manufacturing

NIHL can be caused by a single exposure to loud noise such as an explosion although this is a rare event. More typically, the condition will be caused by repeated exposure to moderately loud noise. While an operator may feel that he/she has become used to the noisy environment, their ears could be taking strain without even noticing it. High levels of noise damage the delicate structures of the inner ear and, over time, can lead to hearing loss. Since there is no way to repair these cells, the damage is permanent. The risk of hearing loss due to exposure to noise is especially high among factory and heavy industry workers. Some of the worst tools for hearing damage include saws, drills, punch press, angle grinders, rotary hammers, milling, diecast and moulding machines to name but a few.

Hearing damage may hinder the lives of those it affects and can have a detrimental effect on a person’s health and wellbeing. Hearing loss can have a range of implications including irritability, anger, fatigue, tension, stress, depression, avoidance or withdrawal from social situations.

Preventing noise-induced hearing loss

Noise levels and the duration of exposure contribute to hearing damage but there are many practical, cost-effective measures to prevent this, including:

- Machinery noise reduction measures

- Engineering and acoustic solutions

- Adequate hearing protection

- Health surveillance.

The key to safeguarding hearing and employers, managers and employees need to understand the risk of unprotected noise exposure.

Under the Control of Noise at Work Regulations (2005), employers are required to identify where there may be a risk from noise and who is likely to be affected, monitor noise levels and estimate exposures against published guidance, take noise-control action measures, provide health surveillance as required and deliver training.

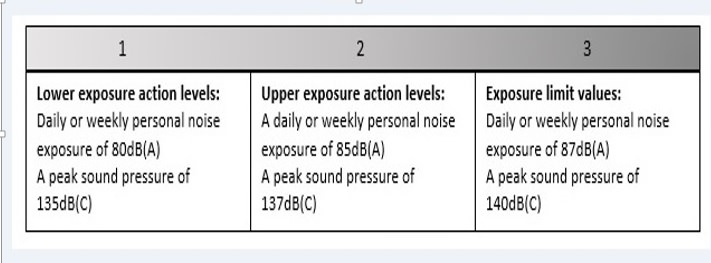

The regulations expect employers to take specific measures at three defined noise levels. It is important that you familiarise yourself with these and implement any recommendations as part of your hearing conservation programme.

Which noise measurement equipment do you need?

In order to comply with the noise regulations, you will need to measure noise levels regularly using a compliant sound level meter. However, handheld noise measurement devices are not always the best solution in practice. If you are looking to monitor the workers’ average noise exposure throughout the day, but their jobs involve a lot of movement from one workstation to the next, a personal noise exposure meter worn on the shoulder throughout the duration of the shift such as our noise dosimeters may be a more practicable option. For both options, any data collated should be used to reduce the noise intensity at source or, if this is not possible, select appropriate hearing protection.

Recommended products

-

Nova Noise at Work Sound Level Meter

From: £1,605.00 (Ex. VAT/GST) -

NoisePen Personal Sound Exposure Meter

From: £499.00 (Ex. VAT/GST) -

SafeEar Noise-activated Warning Sign – Hearing Protection Must Be Worn

From: £342.00 (Ex. VAT/GST)

If you or your company requires professional guidance to help prevent noise-induced hearing loss in manufacturing or engineering, Pulsar Instruments can help. We have a wide range of compliant sound level meters, personal sound exposure meters and associated equipment to suit virtually every workplace application.

Pulsar also delivers workplace noise awareness and product competency training in small groups at various venues in the UK or at your premises by prior arrangement. We offer free product demonstrations in the UK. To book yours, simply ring us on 01723 518011 and we will be happy to arrange this for you.

Supporting information

Pulsar Instruments have produced a number of support documents for managers in the manufacturing industry including a FREE downloadable e-guide: 5 Steps to controlling noise at work.