As a safety manager, your job is to protect your employees from harmful noise levels in the work environment. Your first step is to identify whether there is a problem or not, and whether recommended noise levels specified in the Regulations have been breached. Often, common sense observations will suffice. But, if a hearing risk is identified, your line of defence going forward is to conduct a noise assessment.

Here we list 5 basic steps for you to follow.

1. Simple observation: Do you have a noise problem at work?

- The noise is noticeable but does not interfere with normal conversation

- Workers have to shout to be heard by colleagues if they are more than 1m apart

- Workers use noisy power tools or machinery for more than half an hour a day

- Do workers tense up when the noise starts?

- Do they relax when the noise stops. Do they walk away?

- Have workers reported headaches, loss of hearing or stress after leaving work?

If you have answered ‘yes’ against any of the above, you need to investigate further and test your working environment for dangerous noise levels with professional measurement equipment.

2. Noise assessment: Measure sound levels

Noise is measured using a sound level meter which reads sound pressure levels in dB(A) and the dB Peak sound pressure which is the highest noise level reached by the sound. There are three types of noise meters available for this type of job – Sound pressure level (SPL) or basic, integrating averaging sound level meters and personal sound exposure meters or noise dosemeters. Basic sound level meters tend to cost less and are best used when the noise levels are continuous at a near constant value. Integrating sound level meters provide an average (continuous equivalent noise level or LAeq) over a particular period of time which is important when there are wide variations in sound levels. Finally personal sound exposure meters are in effect integrating sound level meters designed in such a way that they can capture daily personal noise exposure of a worker (Lep,d) measured over the working day. Noise dosemeters are worn on the body or fixed to a hard hat next to the ear.

3. Noise assessment: Noise action levels

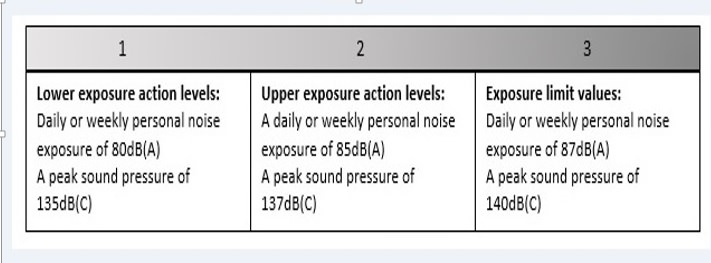

This is something that we mention often in this blog. In the UK, the Control of Noise at Work Regulations (2005) places a duty on employers to reduce the risk from harmful noise to the lowest level reasonably practicable. The UK regulations derive from the EU legislation Directive 2003/10/EC – Physical Agents – noise. Therefore it is applicable to all member states. Outside the EU, similar control levels are in place. You should research your own legislation if you are not sure.

For further guidance on noise assessment and surveys, you may want to consult the HSE website.

4. Noise assessments: Best practice

- Take measurements at arm’s length at working stations of employees closest to the source of noise. The microphone should be held where the workers’ ears are typically found.

- Undertake measurements for as long a period as possible especially if there is a variation in noise levels

- Make a reliable estimate of your employees’ exposures, and compare the exposure with the exposure action values and limit values. Record the LAeq and dB(C) Peak value

- Specify which sound level meter/sound exposure meter was used and the date of its last calibration

- State how many employees are using the equipment, usage and other work duties

- State the condition of the machine and its maintenance history

- Indicate the work being done on the equipment at the time of the assessment

- Include a plan of the work area showing the location of the machine being assessed

- Include other noise sources that may be relevant

- Add recommendations for future actions

5. Review the situation

Finally, we recommend that you continuously review your risk assessment if circumstances in your workplace change and affect noise exposures.

We hope this article has given you a broad overview of what is involved in workplace noise assessments. This is a quick summary, of course, and the work involved will necessitate a high level of detail to act as a reference.

For more information on how to manage noise risk at work, the Control of Noise at Work Regulations (2005) and noise-induced hearing loss, have a look at the following:

For detailed information and specifications on our range of noise measurement products to help you conduct your noise risk assessment, please contact us or ring us on 01723 518011 to talk to one of our advisors.

For more online noise at work measurement tips and ideas, subscribe to this blog.

If you would like to discuss conducting your own noise assessment surveys with our noise measurement equipment, contact us today!