Construction Noise Products from Pulsar Instruments™

-

Pulsar Nova Outdoor Noise Measurement System (WK3)From $2.254,00 (Ex. VAT/GST)

Pulsar Nova Outdoor Noise Measurement System (WK3)From $2.254,00 (Ex. VAT/GST) -

Low-Cost Decibel Meter – Pulsar Nova Class 1From $2.220,40 (Ex. VAT/GST)

Low-Cost Decibel Meter – Pulsar Nova Class 1From $2.220,40 (Ex. VAT/GST)

Construction Noise Monitoring and Measurement

Pulsar Instruments have several solutions for construction noise assessments including sound level meters with the ability to effectively monitor the following two key categories:

- Noise at Work (potential for noise-induced hearing loss due to sudden or long term exposure to noisy activities)

- Environmental Noise (the potential to cause annoyance to surrounding areas during construction work)

Both of these key areas can be assessed by Pulsar Instruments’ fully compliant, accurate, easy to use and, most importantly, robust construction noise monitoring and measurement equipment to help you address these particular noise issues effectively.

How to carry out construction noise assessments

Construction noise and demolition noise

The construction sector and its wide range of associated activities are very varied and, from a noise monitoring perspective, offers many unique challenges.

Exposure to many different sources of Construction noise on a site has a cumulative effect and cause hearing damage, even if a worker is only exposed to a single source of noise over a short time. If workers leave the site at the end of their shifts with muffled hearing, even if it is better by the next morning, damage may have already occurred. Under the Noise at Work Regulations (2005), employers have a duty to protect workers and take steps to reduce the risk. Furthermore, the Construction Industry is different from, for example, factory and manufacturing because work patterns vary considerably and projects can last from a few days to a few years.

Construction noise assessments must adhere to in-country standards, for example, in the UK BS 5228 -1:2009 is the ‘Code of practice for noise and vibration control on construction and open sites’. This code provides guidance on the methods that can be used to predict and measure noise from construction activities and how to assess the impact on those exposed to it.

The other impact of Construction Noise is on the surrounding environment and the communities that live in the vicinity.

Noise from construction can be an annoyance and a stresser to humans and animals.

Basic construction site noise level checks

Often on-site, you need to take quick decisions and understand if there are likely to be any noise at work or environmental noise issues. By using a simple ‘sound level meter’ such as the Pulsar Model 14 you have a cost-effective, ideal, compact and ‘easy to use’ instrument that can be transported from site to site allowing you to make a quick judgement regarding noise levels.

This is particularly useful where a more expensive instrument would be cumbersome and at risk of on-site damage or misuse. The Model 14, low-cost noise meter is supplied with a carrying pouch and windshield as standard to protect the microphone capsule and has two selectable ranges to allow you to quickly gauge both environmental and industrial level noises.

The instrument is a Class 2 sound level meter which is perfectly acceptable to conduct noise assessments under the current noise regulations. It is fully compliant with IEC 61672 and can be supplied with an acoustic calibrator if you wish to verify the accuracy of your measurements.

Using noise-activated warning signs

Large noise warning signs such as the Pulsar SafeEar Max can communicate noise safety messages to your workforce across large and complex development sites effectively.

The large signs light up when pre-set noise levels are exceeded to warn visitors and workers alike when hearing protection is needed. The highly-visual LED technology is further complemented by a large flashing beacon. Signs such as these will help you monitor and record ambient noise as well as alert staff to dangerous noise levels.

The SafeEar Max can be put at a fixed point, for example on a wall, or it can be used with a heavy duty tripod and moved to difference locations.

Another alternative is the SafeEar Noise-Activated Safety System. This mobile noise-activated safety system has been developed in collaboration with Interserve. It can easily be moved construction sites to focus on noisy areas, it’s also weatherproof and has long-life rechargeable batteries included. This large visual noise indicator system will warn workers, visitors and other operatives when hearing protection is needed. The system includes a hearing protection dispenser for easy application of hearing PPE when the need arises.

Assessing noise impacts on construction workers

Pulsar Nova sound meter used for construction noise monitoringWe recommend that you consult our latest range of Nova sound level meters and, in particular, our Model 43 (Class 1) and 44 (Class 2) which are the best instruments for performing noise at work assessments. With both these instruments, you can add data logging and octave band filters so they are able to automatically provide the correct level of hearing protection needed. This is crucial on a busy site as ‘over protection’ can isolate workers who may not be able to hear alarms or communicate effectively. Being badly injured by moving plant or objects because you can’t hear what is happening (or warnings from colleagues) is something that can easily be avoided.

If you need to monitor workers noise levels during a shift for instance, giving an overall exposure at the end of each working day, then our range of wearable dosemeters will be useful. The Noise Dosimeter Badge system is very useful in noise assessments and noise monitoring on-site. It is small, robust, dust proof and has no buttons or cables so it doesn’t interfere with work patterns or duties. It provides a continuous noise monitoring system for workers to ensure compliance with HSE guidelines and Noise at Work Regulations. .almost all Noise at Work applications, especially as it is so small that it does not interfere with work patterns.

Or perhaps you might prefer the robust, simple to use and ‘no-nonsense’ approach provided by the Assessor range, Industrial Sound Level Meters, allows even inexperienced users to quickly take sensible measurements that allow you to ensure that your workforce is protected from the effects of excessive noise exposure. They provide you with all the tools required to carry out your noise risk assessments, cost-effectively and accurately determining suitable hearing protection with their special ‘C minus A’ measurement mode.

You can quickly refer to the HML values provided by the hearing protection manufacturer for specific muffs, inserts etc and by using a simple spreadsheet (like the HSE calculator), ensure you are not over or under protecting your employees.

We have produced a short Guide for Employers entitled: ‘5 Steps to Controlling Workplace Noise’. The document looks at the various duties under the Control of Noise Regulations (2005). You can Download your FREE Guide here.

Assessing environmental noise impacts of construction

Noise assessments or environmental noise monitoring can be undertaken at many levels from a simple ‘spot check’ measurement (to determine if there is the likelihood of a problem) to a continuous monitoring system (to ensure continued compliance with local authority recommendations). The Nova can also be used as an ambient noise meter to take background noise level readings.

We recommend that you consult our latest range of Nova sound level meters and, in particular, our Model 45 (Class 1) and 46 (Class 2) which are the premium instruments of this range and suitable for boundary and environmental noise measurements. They are available with an outdoor kit and data logging to allow continuous noise monitoring 24/7 over a longer noise monitoring period.

Another excellent instrument for both Industrial noise and environmental noise applications is the Pulsar Quantifier range of sound level meters, which is used on many UK sites to measure noise.

Other types of construction noise measurements and monitoring

Simple spot check

It is often useful to determine that potentially noisy activities are not likely to reach excessive levels at sensitive boundary positions (usually nearby local domestic housing or offices). The Model 14 would be a low-cost solution for this type of monitoring. The powerful Class 1 Model 33 sound level meter allows you to compare average noise levels at boundary positions against the L90 (typical background noise levels). The Pulsar Nova Models 41 and 42 are also suited for basic noise level assessments.

Single or repeated ‘fixed duration’ measurements

In some cases, a handheld instrument such as the Pulsar Quantifier Model 95 (Class 1) or Model 95 (Class 2) would be mounted on a tripod at a boundary position and, for example, a 15-minute measurement made. Often it is necessary to make a continuous series of similar ‘fixed duration’ measurements and store these into the instrument’s memory for which the Pulsar Model 33 is ideal.

Increased construction also leads to increased noise from vehicles through heavier traffic, larger vehicles and noise from reversing vehicles. Find out how our sound level meters can be used to monitor this too.

Frequency Information

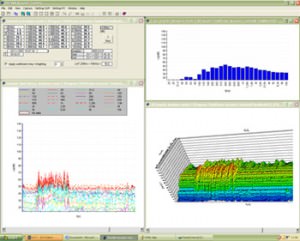

In some cases, noise sources such as extraction fans and wind turbines can cause annoyance at specific frequencies. It is often a requirement to monitor real-time 1:3 Octave Band noise levels to determine when these events are occurring and the likelihood of annoyance.

Tonal Analysis

There are many engineering solutions available to reduce noise levels and by performing a 1:3 Octave Band Analysis before and after this work you can determine and report the effectiveness of such improvements.

Solutions for reducing construction noise

The construction industry is one of the noisiest industries due to the very nature of the work that takes place and that it is difficult to avoid worksite noise, and as a result it is hit harder by hearing loss than many other industries. Hearing loss is particularly common in construction because of the implications of long durations of exposure to lower levels of noise around 85dB(A).

Ways to reduce noise can include:

- Making sure equipment is properly maintained

- Adding oil to equipment to make sure moving parts move freely

- Moving things like air compressors away from where people are working if possible

- Applying mufflers to equipment where possible

- Using acoustic barriers if appropriate

- Educate and train staff in noise awareness and the implications of hearing loss.

These ways may not reduce noise to a level where it’s no longer a hazard or to below the noise action values of 80 and 85dB(A), if that is the case then the effective hearing protection should be provided for levels of 80dB (A) and above, and must be worn for levels of 85dB(A) and above. Health and Safety Officers should also make sure that construction workers are trained in how to wear their hearing PPE correctly.