HAV you got vibration covered? We HAV

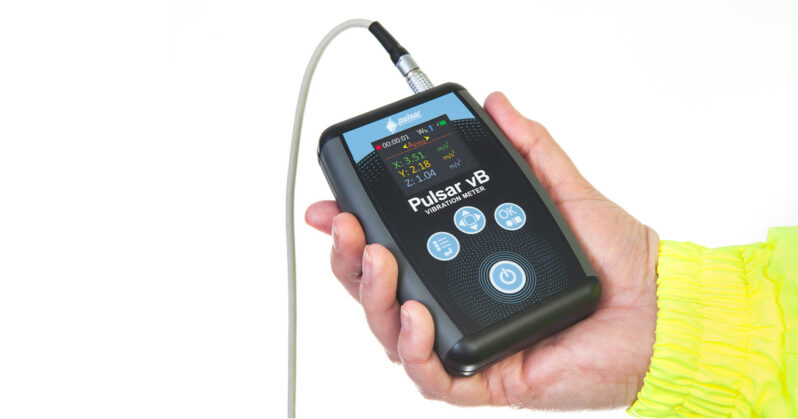

Pulsar Instruments Plc April 2018 – Already well-known worldwide for their reliable and robust noise measurement products, Pulsar Instruments is extending their current health and safety focused product ranges to include a hand arm vibration meter – the Pulsar vB.

Measuring individuals’ exposure to vibration from the use of power tools and machinery is becoming even more important in the workplace. Workers exposed to excess vibration can end up with significant conditions related to Hand Arm Vibration Syndrome (HAVS) including painful and disabling disorders of the blood vessels, nerves and joints such as Vibration White Finger and vibration related Carpel Tunnel Syndrome (CTS).

The Control of Vibration at Work Regulations 2005 requires that employers make sure that risks to employees from vibration are assessed and controlled. With this is mind we believe that the Pulsar vB is the only vibration meter you’ll need, it’s fully compliant with the Regulations, and it will help you accurately measure the vibration levels of your tools, and the exposure levels to your employees.

- Easy to use: just attach it securely to your tools, switch on and press record;

- Essential measurements: it measures all the essential parameters you need for HAVS risk assessments; and,

- Effortless reporting: comes with Pulsar vB Plus software for effortless analysis and reporting too.

Can you afford not to measure vibration?

To give you some idea of the scale of the issue, in a 1999 study by the UK MRC 4.8 million people worldwide were estimated to be at risk of HAVS, of these c. 1.7m exposed above the EAV, and c. 1m exposed above the ELV. HSE estimates that in the UK 2 million people are a risk of vibration exposure everyday and that VWF claims now represent 9% of all employers’ liability cases, and it is the most reported injury under RIDDOR.

The UK HSE research indicates that it costs a company between £7000 and £36,000 to process every £1000 paid out in claims. A significant proportion of this cost is a consequence of both the quality and the difficulties inherent in extracting historical information from past assessments in different formats.

Recent High profile compensation claims* include:

- £1.2M payout (2000) North West Water: 8 former employees

- £400k (reduced to £150k) (2017) Wrexham County Borough Council: 12 workers

- £250k (2016) Thanet Council: 12 workers

- £200k award (April 1998) to a tree surgeon employed by Liverpool CC

- £143k award (April 1998) to British Gas fitter: a total of £420k to 6 fitters.

- £124K award (sept 1997) to 7 British Coal Miners: suns ranged from £5k to £41k

- £120k (2017) Newfield Fabrications: 2 workers

- £118K (2011) DSM Demolition Ltd: 1 worker

- £100k fine + costs (2017) for Charter Housing Association: 6 employees affected

- £50k (2018) Design and Supply Ltd: 1 worker

- £30k (2018) Tai Calon Community Housing: several workers

- £500k (2018) Balfour Beatty (following fines of £120k in 2017, and £250k in 2016)

- £400k (2018) Nordam Europe Limited (+£39k in prosecution costs).

- £80k (2018) British Airways Avionic Engineering Limited (+£25K costs) pleaded guilty to breaching Control of Vibration at Work Regulations 2005

- £60K (2018) Calderys UK sentenced for failing to control exposure to both vibration and silica for its workers

- £20K (2019) Calico Homes Limited, Burnley fined £20,000 and ordered to pay costs of £4,335 by the HSE.

- £90K (2019) Faiveley Transport Tamworth Ltd, pleaded guilty to breaching Section 2 of the Health and Safety at Work etc. Act 1974. Was also ordered to pay costs of £45K.

*(not including legal costs)

Start tackling HAVS in your workplace and ensure your employees are protected from vibration exposure injuries.

Contact Pulsar Instruments today Phone: 01723 518 011, email [email protected]

The Regulations

The Vibration Regulations include an exposure action value (EAV) and an exposure limit value (ELV). Employers’ duties are to reduce the risks from vibration to the lowest level reasonably practicable and to reduce exposure to as low as is reasonably practicable if it is above the EAV. You must not allow exposures to exceed the ELV. If you comply with the Vibration Regulations you will prevent disability from HAVS and vibration-related CTS. In the UK, certain cases of HAVS and all cases of vibration-related CTS must be reported to HSE in accordance with the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations (RIDDOR).

More information for employers can be found in HSE’s publication “Hand-arm vibration at work a brief guide”

HAVS Facts (HSE 2018)

- HAVS is preventable, but once the damage is done it is permanent.

- HAVS is serious and disabling, and nearly 2 million people are at risk.

- Damage from HAVS can include the inability to do fine work and cold can trigger painful finger blanching attacks.

- The costs to employees and to employers of inaction could be high.

- There are simple and cost-effective ways to eliminate risk of HAVS.

- The Control of Vibration at Work Regulations focus on the elimination or control of vibration exposure.

- The long-term aim is to prevent new cases of HAVS occurring and enable workers to remain at work without disability.

- The most efficient and effective way of controlling exposure to hand-arm vibration is to look for new or alternative work methods which eliminate or reduce exposure to vibration.

- Health surveillance is vital to detect and respond to early signs of damage.

You might also like

- Introducing the Pulsar vB

- Noise and vibration consultants

- HAV some common sense

- Vibration White Finger and Secondary Raynaud’s

- HAVS Tool Testing

Find out about our range of HAVs meters.