“Practical advice on ways to carry out Noise Control and reduce noise at work, including how to select the correct level of hearing protection and carry out noise reduction activities.”

Reductions in reported cases of noise-induced hearing loss (NIHL) from noise at work appear to have taken place in recent years with a considerable fall in the number of new claims and numbers of affected workers. However we’re now at the point that further reductions in NIHL will require much better noise control and much earlier interventions especially for high risk workers.

As published in May/June 2018 Industrial Plant and Equipment Special Supplement on Health & Safety

According to HSE data reported incidences of work-related hearing loss have decreased and the number of new claims for work related noise induced hearing loss has almost halved as Health and Safety Professionals become increasingly aware about taking precautions with their employees’ hearing. However the ‘go to’ noise control solution many companies employ is a blanket approach to providing hearing protection – and they are over-prescribing it, either through the amount of time individuals have to wear such protection (e.g. all day, every work day), or with the ‘strength of protection’ afforded in a sticking plaster type approach. Often the attitude of getting the strongest protection possible prevails. Whilst this may have had some success in getting incidences of NIHL down it is problematic for both the worker and the company in the long run. Over-prescribing hearing protection can block workers’ ability to communicate with each other which can become isolating, increase occurrences of poor job satisfaction, depression and staff sickness, and decrease their productivity. Of more immediate impact, it can impair workers ability to hear fire alarms, other emergency messages or, for example, vehicles reversing placing them at risk of other dangers.

There is also some anecdotal evidence that over-prescribing hearing protection leads to workers neglecting to wear it ‘the comfort and hygiene factors’ or, when they do, they wear protection that is not well-fitted or use it incorrectly. (Refer to our Guide to selecting the correct level of hearing protection for support).

Why reduce NIHL?

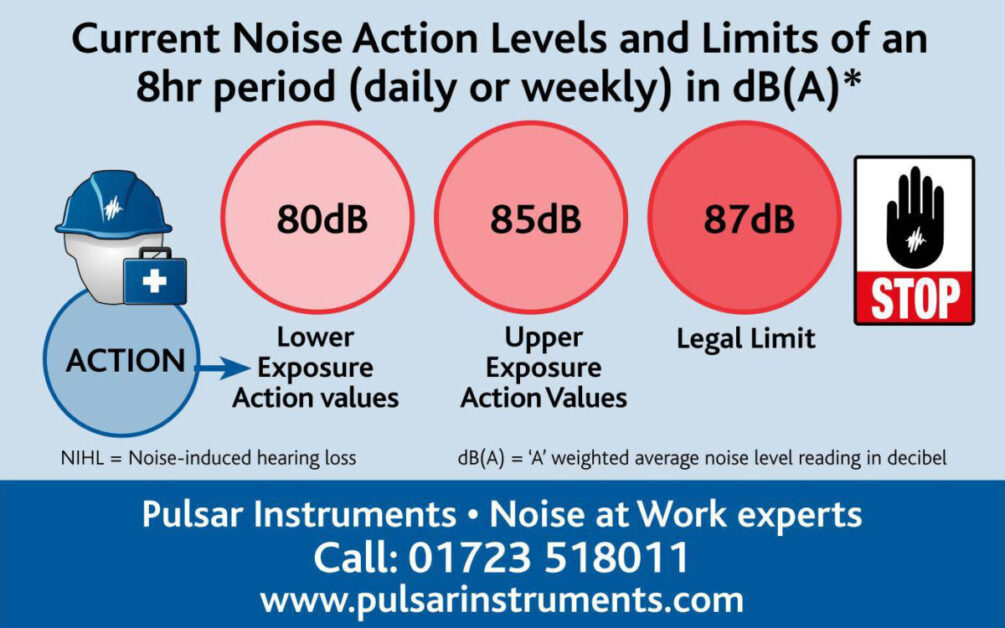

As responsible employers, you have a legal obligation under the Control of Noise at Work Regulations (2005) to safeguard the hearing of your workforce. Disregarding this can lead to civil compensation claims for industrial deafness resulting in loss of revenue and negative impacts on business reputation and ability to recruit and retain competent staff.

The degree of damage to hearing is determined by both the level of the noise and the length of exposure.

So what is the long-term solution?

No one is suggesting that we stop using hearing PPE but that it should be a last resort, instead companies should focus on reducing noise at work in situ. Though many of us are all far more aware of noise and its impacts these days, there are still many work sites, factories and the like with too much noise. The HSE advises companies to put emphasis on control of noise at source and rely less on PPE, carry out better surveys and reporting, and perform health surveillance for people with noise exposures of 85dB(A) or above (or in such locations where it is difficult to eliminate risks). Such audiometric surveillance is expensive so often the most practical long term solution is to reduce noise at source.

In 2015 Pulsar Published its Guide for Employers “5 Steps to Controlling Workplace Noise”, whilst this Guide remains very relevant, if we are really going to ‘manage out’ workplace hearing loss then we need to look beyond this to include early intervention such as:

- Conduct comprehensive noise assessment surveys and measurements using suitable Class 2 sound level meters (such as the Pulsar Nova) to identify

- which employees are at risk, and

- where and when are they at risk.

- Carry out noise abatement work or engineer solutions to control noise at source.

- Repair, replace or upgrade noisy machinery.

- Mark out areas of concern and provide appropriate noise-activated warning signs such as the PulsarSafeEar.

- Establish a buy quiet policy and company noise policy.

- Provide training and education for all staff.

Going forward

As the person responsible for health and safety in your workplace your primary noise control aim should be to reduce noise in the workplace and then apply the correct level of PPE as a last resort (Refer to our Guide for support).

Practicalities may seem to dictate that PPE is the only solution for many companies but for long term control and maximum benefits companies should always try to put noise control measures in place first wherever possible.

You might also like

Other blog posts:

- Understanding-3db-rule

- 80-85-and-87-decibels-why-these-values-matter

- What is a noise survey?

- Guide to common noise measurement terms

Pulsar Instruments Plc are noise at work experts. We help companies take control of noisy workplaces by providing the right noise measurement tools, the right noise awareness training and the right support.

Contact us for more information T: 01723 518011 Email: [email protected]